What Is a Conversion Cost?: Comprehensive Guide

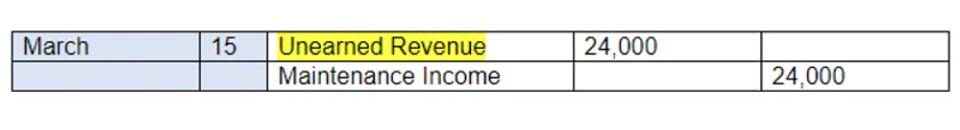

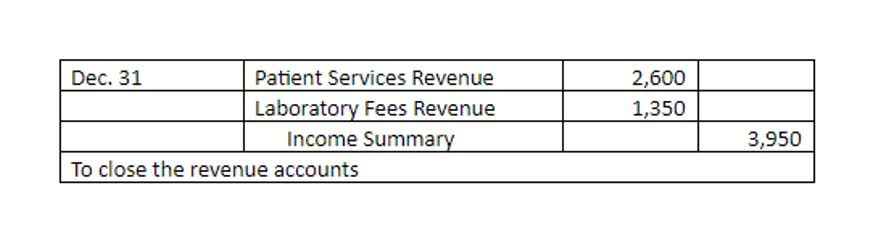

It should be aligned with the strategic goals and vision of the organization. The cost of conversion analysis should not be done in isolation, but rather in conjunction with the overall strategy and vision of the organization. It should support and contribute to the mission, values, and objectives of the organization, such as growth, innovation, sustainability, and social responsibility. It should also be communicated and shared with all the relevant stakeholders, such Accounting For Architects as owners, managers, employees, customers, and suppliers, to ensure their understanding and commitment. Conversion costs are reported in cost of goods manufactured (COGM) statements, providing stakeholders with transparency into production expenses. Imagine an e-commerce company that wants to increase its conversion rate (the percentage of website visitors who make a purchase).

Conversion Cost vs. Other Costs

Most bathrooms include a bathtub/shower combo, but conversion cost modern homes are often fitted with a walk-in shower instead. Luckily, a bathtub-to-shower conversion is not only possible, but it’s also a relatively affordable option, especially considering the value it can add to your home. Discover what a production management system is, its importance, functions,…

- These are some of the main differences and similarities between the cost of conversion and the cost of goods manufactured.

- Many successful van lifers start with basic conversions and upgrade systems over time as budget allows.

- Conversely, higher conversion costs may indicate inefficiencies or higher quality craftsmanship, which could justify a premium price point.

- For example, if the conversion cost per unit is $9 and the raw material cost per unit is $3, the total production cost per unit is $12.

Conversion Cost Formula: What It Means & How to Use It

- In the world of online marketing, understanding the quality score is key to improving the efficiency and profitability of your campaigns.

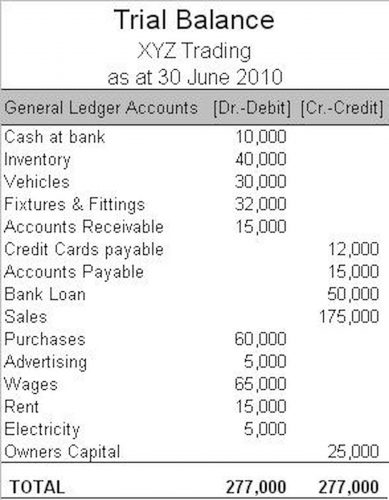

- How to use conversion cost for cost accounting purposes, such as assigning costs to products, inventory valuation, and variance analysis.

- By implementing these tips, businesses can effectively lower their conversion costs, improve their profit margin, and achieve greater profitability.

- To get the most accurate estimate for your garage conversion, consult with a local contractor familiar with your state or region’s pricing structure.

- Factors that can impact conversion cost include labor wages, energy costs, cost of raw materials, and efficiency of the production process.

- Alternatively, a business experiencing high manufacturing overheads might seek ways to streamline its production process to reduce waste and lower costs.

Every custom cabinet, unique layout modification, or one-off feature adds time and cost. While customization can be worth it for specific needs, it’s often more cost-effective to find a standard layout that works well and customize finishes rather than functionality. The difference between basic and premium materials can add $10,000+ to a build. Led by editor-in-chief, Kimberly Zhang, our editorial staff works hard to make each piece of content is to the highest standards. Our rigorous editorial process includes editing for accuracy, recency, and clarity. Professional installation for a tub-to-shower conversion can take as little as 2 days if your shower will have the same dimensions as the old tub and you choose a prefabricated shower body.

Van Conversion Cost Breakdown (With Real Examples)

Knowing this allows businesses to determine pricing for their products more accurately. In summary, calculating conversion cost involves considering direct labor, direct material, and manufacturing overhead. By managing these components effectively, businesses can enhance their competitiveness and financial performance.

These individuals operate machinery, assemble assets = liabilities + equity products, and perform other labor-intensive tasks. Calculating direct labor cost involves multiplying the total hours worked by the labor rate (hourly or per unit). Businesses must carefully allocate these costs to ensure fair pricing, efficient resource utilization, and sustainable operations. By understanding the nuances of indirect costs, companies can make informed decisions and optimize their production processes.